Basic Knowledge about Enameled Aluminum Wire

2016-01-04

Enamelled aluminum wire is one of the main varieties of the winding wire which is composed of a conductor and an insulating layer. Bare wire soften after annealing, and then several pain, finally bake. But it is difficult to produce that meet the standard requirements, but also to meet customer requirements. It is subject to raw material quality, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of enameled aluminum wire and enamelled copper wire does not the same. but are equipped with mechanical properties, chemical properties, electrical properties, thermal properties of the four properties.

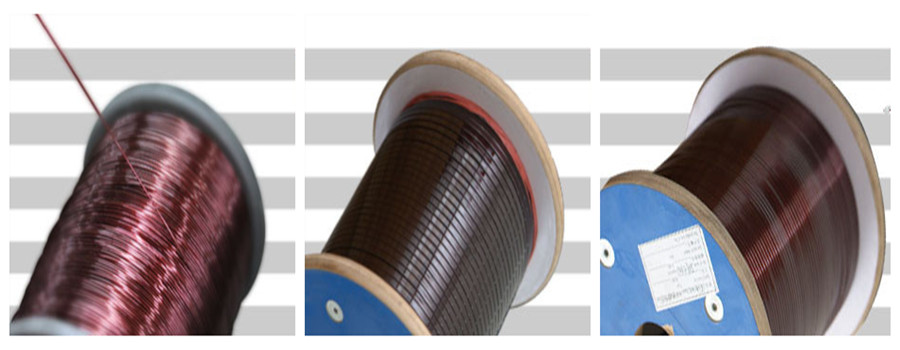

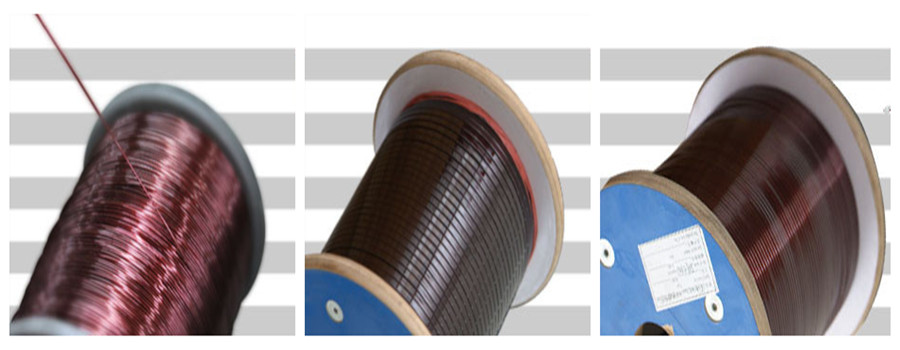

Enamelled aluminum wire

Enamelled aluminum wire has high heat resistance, excellent mechanical properties, electrical properties and chemical properties and excellent resistance to freezing performance. It can apply for refrigeration equipment under 200 ℃ long-term work conditions and electrical equipment, dry-type transformers, oil-immersed transformers and epoxy cast transformers by chemical erosion. And enameled aluminum wire also can used in separators, electromagnets and other electrical equipment. Enamelled aluminum wire is not only used for the equipment, or the main raw material of aluminum arts artists commonly. Enameled aluminum wire originally used in handicrafts, which is a column of aluminum arts master Yang Hao whim utilization. Its special color and physical properties determine the elegant handicrafts. After a long article prepared, the handicraft can be keep for a long time.