- HOME

- PRODUCTS

- ABOUT US

- Panorama

- Download

- NEWS

- CONTACT

.jpg)

.jpg)

.jpg)

.jpg)

We're here to help:Easy ways to get the answers you need.

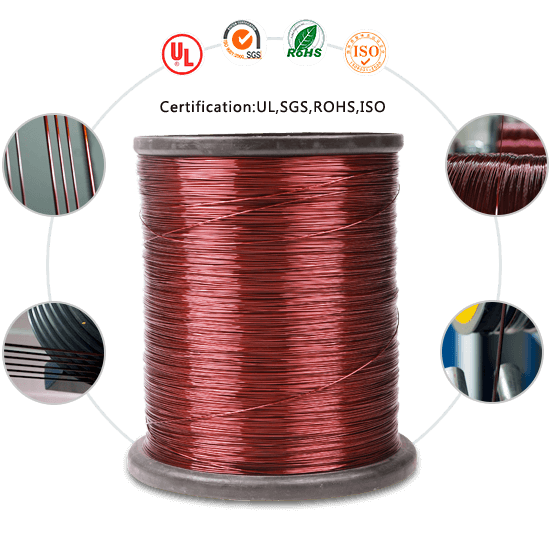

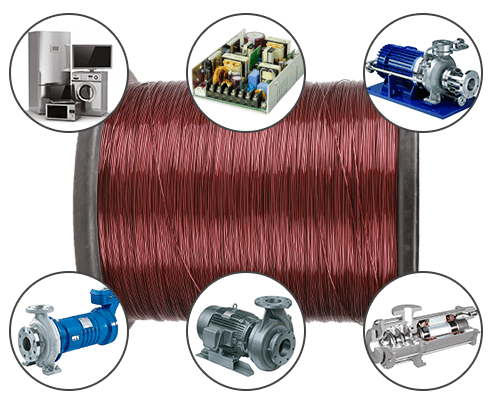

Enameled Copper Clad Aluminum Wire

Size: 0.19-4.0mm

Thermal Class:130,155,180,200,220

Production Characteristics

1.The direct current resistivity of enameled copper clad aluminum wire is about 1.45 times as much as bare copper wire. And when the direct current resistivity is equal, enameled copper clad aluminum wire’s weight is about 0.5 time as much as bare copper wire’s.

2.Our Enameled Copper Clad Aluminum Wire has good solderability like pure copper wire, because our enameled copper clad aluminum wire coated a layer of pure copper . At the same time, our enameled copper clad aluminum wire has thick copper flyer so that our product can ensure its solderability.

3. Our Enameled Copper Clad Aluminum Wire’s density is o.4 time as much as pure copper wire, so it can reduce the weight. And it can save more than 30% cost, if enameled copper clad aluminum wire replaces pure copper wire.

4. Another advantage of our Enameled Copper Clad Aluminum Wire is that aluminum wire has higher heat resistance compared to copper wire according to NEMA.

5. Enameled Copper Clad ALUMINUM wire is more flexible and easier to install than copper wire.

Insulation: ELANTAS

| Item | Requirement of the standards |

| Stardards | IEC 60317-15 |

| Electrical resistivity | <0.006354Ω mm²/m |

| Breakdown voltage | 5000V |

| Heat shock | The minimum Heat shock temperature 200,220,240℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320,360,400℃, 2mins not break down |

Please fill in your procurement needs and contact information