- HOME

- PRODUCTS

- ABOUT US

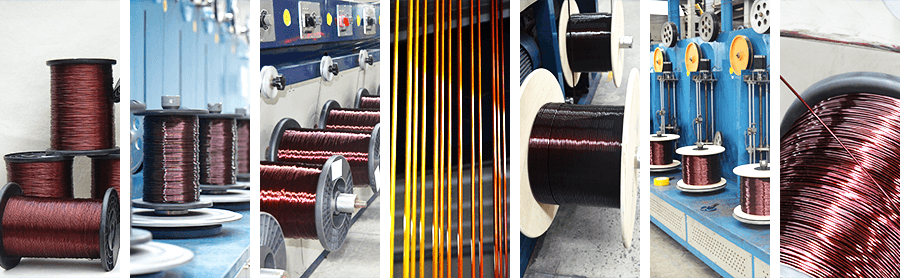

- Panorama

- Download

- NEWS

- CONTACT

We're here to help:Easy ways to get the answers you need.

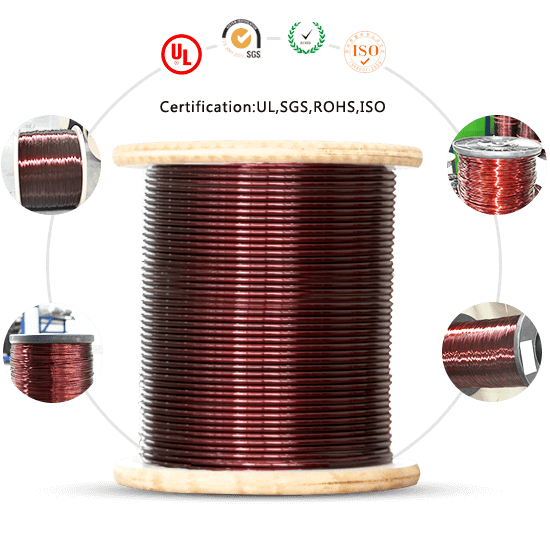

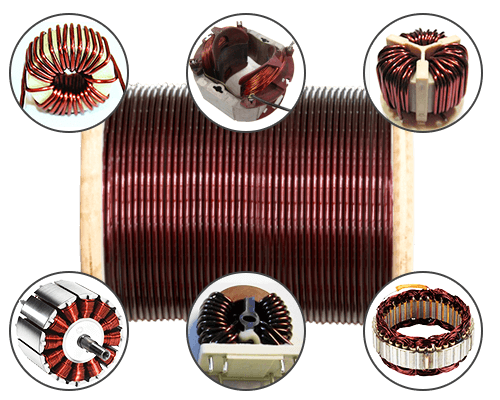

Enameled Round Aluminum Wire

Size: 0.2-8.0mm (AWG 32 – AWG 1)

Thermal Class:130,155,180,200,220

Production Characteristics

.png)

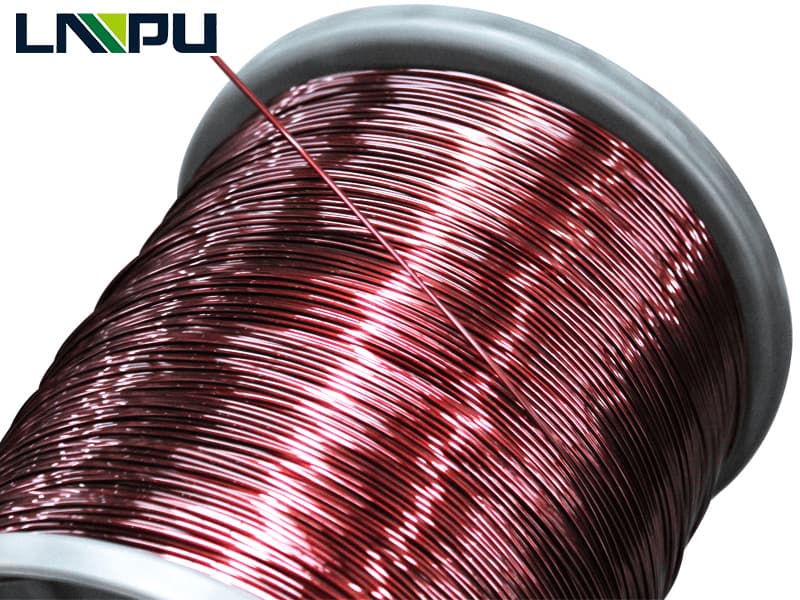

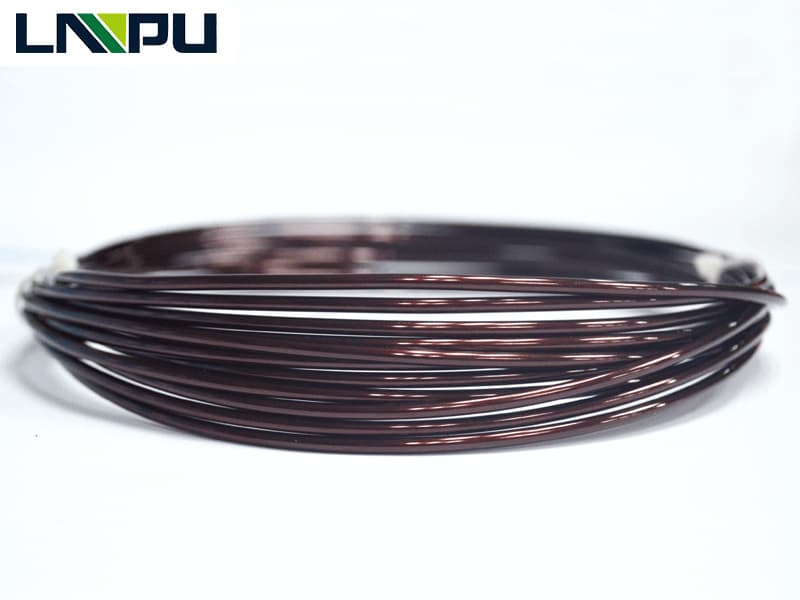

1.Appearance: light brown/Purplish, Smooth and bright, free from lacquer wart.

.png)

2.The material of Enameled aluminum wire: Drawing or extruding bare aluminum wire confirm to national standard.smooth surface,no defects Good perfoamance insulation enamel,polyester or polyester-imide over coated with Polyamide-imide.

3. Enameled aluminum wire is more easily to be coils than enameled copper wire. Because of having a solid layer of oxidation film, enameled aluminum wire have better insulativity and longer life length.

4. Enameled aluminum wire’s flame-retardant level is B, so it has good better shielding effectiveness and high mechanical property.

5. The biggest advantage of aluminum wire is its weight. It is three times as light as copper wire. so it can reduce cost. And it has better adhesion, so it can reduce transportation expenses and add value-added.

6. Our enameled round aluminum wire has good heat resistance, chemical corrosion resistance ,transformer oil resistance, low temperature resistance radiation resistance, good stability, good mechanical properties.

Insulation: ELANTAS

.png)

Maximum size :8.0mm

Intelligent on-line monitoring equipment

| Item | Requirement of the standards |

| Stardards | GB/T6109/ IEC60317-0-1 GB/T23312/ IEC60317-0-3 MW76-A/ MW35-A |

| Electrical resistivity | 0.017241/0.02785 Ω mm²/m |

| Breakdown voltage | 2500/5000V |

| Heat shock | The minimum Heat shock temperature 200,220,240℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320,360,400℃, 2mins not break down |

Please fill in your procurement needs and contact information